油漆桶压块粉碎机分离器的设备代号它能否高效地处理废旧金属

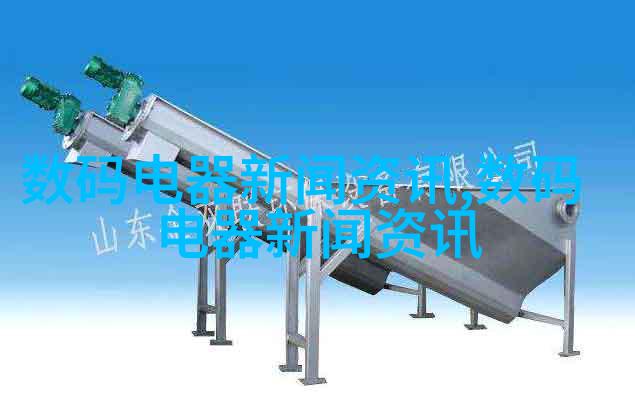

油漆桶压块粉碎机,磁选分离式废旧金属回收系统

metallic waste processing oil drum block crusher with magnetic separation technology.

Metallic waste recycling system, utilizing an oil drum block crusher with magnetic separation technology. This innovative solution effectively processes and recycles metallic waste, achieving a high degree of efficiency and purity in the recovered materials.

The key components of this system include:

Metallic Crusher: The core component of the system, responsible for breaking down metallic waste into uniform particles. The crusher's internal mechanism consists of a rotor, wearing plates, and sieves that work together to efficiently process the materials.

Rotor: A critical part of the crusher, comprising a rotor disc and hammer heads that strike against incoming metal scraps. Constructed from durable manganese steel, these hammer heads ensure efficient crushing performance.

Wearing Plates: Installed on both sides of the crusher body to protect it from wear caused by abrasive materials during operation. These plates also facilitate easy replacement when needed.

Sieves: Determine output size distribution as well as overall throughput speed and quality control for processed material.

This comprehensive recycling system offers numerous benefits:

High-quality output

Efficient energy consumption

Easy maintenance

Reduced operating costs

By leveraging cutting-edge technologies like magnetic separation techniques integrated within our systems can help minimize environmental impact while maximizing resource recovery value.

For inquiries or purchases:

Contact our 24/7 customer service hotline at (310) 0089 663 or reach us via mobile phone [insert number here].

Welcome new and existing customers! We look forward to your call for consultation or purchase assistance!